Armored vehicle based on Toyota LC300

-

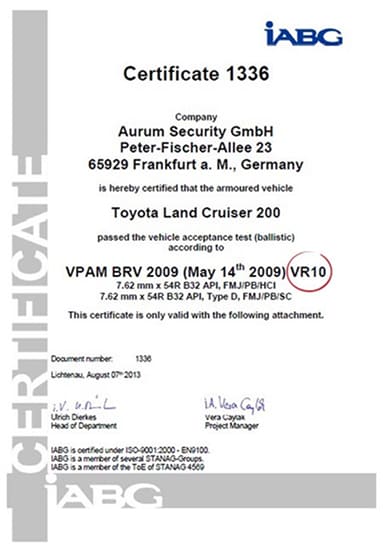

Ballistic protection level

VPAM 7–9 / VPAM VR 10

-

Explosion protection

STANAG 4569

-

Certified by

iABG

-

Qualified by

Lloyd's Register

-

Certified to standard

ISO 9000

The Armored Toyota Land Cruiser 300 is our flagship vehicle, delivering maximum protection without compromising on comfort, performance, or design.

We manufacture the Land Cruiser 300 according to VPAM protection levels 7–9 and VPAM VR 10 — the highest ballistic standard available for civilian vehicles.

Our Toyota Land Cruiser 300 vehicles share the same armoring design with the LC200 series — a platform that has been internationally tested and proven in real-world scenarios.

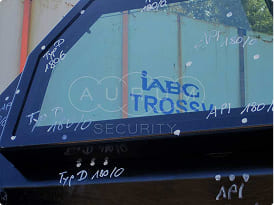

This design was tested and certified by the German military testing facility iABG in accordance with the BRV 2009 standard, protection level VR 10. High-speed cameras and crash test dummies were used to accurately measure the effects of ballistic and blast impacts on the occupants.

From 2013 to 2016, we were the only company in the world to achieve this level of certified protection.

In 2016, Mercedes-Benz followed with their Maybach Guard, also certified to VPAM VR 10.

This protection level is normally possible only for military vehicles, yet our vehicles retain comfort and inconspicuous look of civil SUVs. Please refer to the ballistic protection charts and blast protection charts for more details.

PROTECTION VPAM 10

- Opaque areas including the roof &provide protection according to VPAM APR 2006, level 10 / Stanag 3–. That includes all soft core bullets 5.56, 7.62, 9 and 12.7 mm and all wide-spread hard-core and armor-piercing bullets: 7.62×39 (BZ) Kalashnikov API, 7.62×51 (P80) AP, and 7.62×54 (B32) Dragunov API, from any angle (not only 45° or 90° as per BRV 1999)

- All transparent areas have thickness 80 mm and provide protection according to VPAM APR 2006, level 10 / Stanag 3–. That includes multiple shots of all soft core bullets 5.56, 7.62 and 9 mm and all wide-spread hard-core and armor-piercing bullets: 7.62×39 (Kalashnikov BZ), 7.62×51 (P80) AP, and 7.62×54 (B32) Dragunov API, from any angle (including 90°)

PROTECTION VPAM 7/9

- Opaque areas including the roof provide protection according to VPAM APR 2006, level 7. That includes most of the soft core bullets 5.56, 7.62 and 9 mm, from any angle (not only 45° or 90° as per BRV 1999)

- Transparent areas VPAM 9 (B7, bullet-proof glass 65 mm). All transparent areas have thickness 65 mm and provide protection according to VPAM APR 2006, level 9. That includes multiple shots of all soft core bullets 5.56, 7.62 and 9 mm and the armor-piercing bullets of Kalashnikov 7.62×39 (BZ) and 7.62×51 (P80), from any angle (including 90°).

- 15 kg TNT at 2 m distance from the side of the vehicle, elevation 1 m

- 3 × DM51 grenades under the floor

- 2 × DM51 grenades on the roof

- DM31 (anti-personnel mine) under the floor

- Anti-tank mine (6 kg TNT) under the wheel (Stanag 2a) [optionally]

- 2×DM51 grenades detonated under the floor

- 2×DM51 grenades detonated on the roof

PROTECTION VPAM 10

PROTECTION VPAM 7/9

“VR” means that complete vehicle has been tested and certified, and not only the materials used. So VPAM VR 10 means that complete vehicle was tested and certified to the level VPAM 10, this is the next level after B7.

VPAM is the latest European standard for ballistic protection, which is now used to replace the old commonly used classification levels from B1 to B7.

Core 4.1, Hardness 65

Core 4.6, Hardness 60

Core 5.3, Hardness 63

Our cars do not have ballistic gaps

The armor capsule protects 100% of the cabin. This increases the production time several times and requires a complete rework of the interior, but it is the only way to ensure reliable protection.

During the VR certification our vehicle was tested with 550 shots:

Our vehicles were able to pass VR certification due to the fact that they have an armored capsule – original car body is mounted on the armor and serves solely to preserve the original appearance. Most other companies do the opposite – they hang armor on the original car body. It is cheap and dirty solution but during an explosion the armor sheets will fly apart, becoming so-called secondary projectiles, and it is impossible to protect the entire cabin if all parts of the armor are not interconnected.

Over time even during regular usage cracks start appearing on the car body -it is made of steel only 0.8 mm thick, and it was not meant to hold the weight of 6.5 mm armor.

Engineering & Technology

Armored Capsule

- The design is fully certified and tested as a complete system (not just individual panels).

- Manufactured from a single, continuous armored steel plate.

- All critical areas, including the floor and roof, are fully protected.

- Completely sealed — no weak points.

- Laser-welded or overlapping joints.

Glass

The glazing is 80 mm thick and provides protection in accordance with VPAM APR 2006 (Level 10 / STANAG 3). All windows are multi-layered, including splinter-resistant polycarbonate, ensuring maximum visibility and protection without distortion. Our bonding process guarantees full adhesion to the frame and eliminates the risk of gap formation.

Wheels

Equipped with run-flat tires that remain functional even after complete pressure loss. Combined with reinforced rims and inserts, these systems allow continued driving for up to 50 km at speeds of up to 80 km/h, even with a completely flat tire.

Upgraded Suspension and Braking System

The suspension and braking system are fully upgraded to support the increased weight of the armor without compromising ride quality. Components are recalibrated or replaced to ensure optimal performance and durability under load. The enhanced systems provide safety even during evasive maneuvers.

Contact Us

Get in touch — we'll help you find the best protection solution

65830 Kriftel,

Germany