Armored Toyota Land Cruiser 200 is our flagship vehicle. We produce armored Toyota Land Cruiser 200 according to the protection levels VPAM 7-9 and VPAM VR 10. Our vehicles with protection level VPAM 7-9 share the same armoring design with VPAM 10 ones.

Our Armored Toyota Land Cruiser 200 was tested and certified by the German military testing facility iABG according to the standard BRV 2009, protection level VR 10. The tests were recorded using high-speed cameras and a dummy had been placed inside the сar to register all data necessary to evaluate the effects of the blasts to the occupants of the vehicle.

As of 2013 we are the only company in the world, which have reached this high level; and that is why we can claim that our Armored Toyota Land Cruiser 200 provides the highest protection among civilian vehicles.

We managed to keep the gross weight of the armored car at 4830 kg (where the weight of the base car is 2460 kg); it is only 200 kg heavier than a typical certified VR7 vehicle and provides about 1000 kg payload.

Our cars are made in Germany, but simply because something is made in Germany, it is not automatically better.

What distinguishes our vehicles:

1. We completely tested the entire vehicle, and not just the materials - i.e. our vehicles are VR certified. This is a fundamental difference – like it cannot be said that an usual car is safe until it has passed a crash test, so the armored car which did not pass ballistic and blasts tests cannot be seriously taken as a reliable protection.

2. Despite the highest protection level for civilian vehicles, our armored Toyota LC200 (both with a petrol engine of 5.7 liters and with a diesel engine 4.5 liters) can accelerate to 140 km / h. Acceleration to 100 km / h takes only 12 seconds. Fuel consumption with air conditioning operating at full capacity is 30-34 liters per 100 km for vehicles with a petrol engine and 24-27 liters for vehicles with a diesel engine.

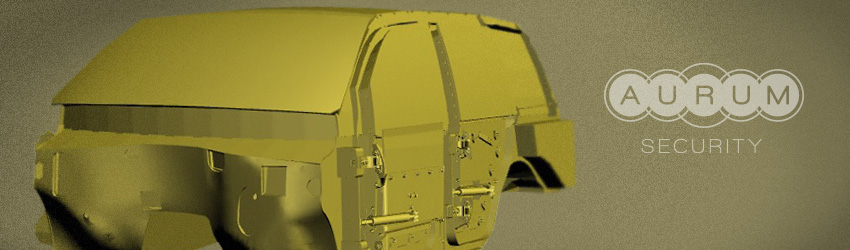

3. Our vehicles were able to pass VR certification due to the fact that they have an armored capsule – original car body is mounted on the armor and serves solely to preserve the original appearance. Most other companies do the opposite - they hang armor on the original car body. It is cheap and dirty solution but during an explosion the armor sheets will fly apart, becoming so-called secondary projectiles, and it is impossible to protect the entire cabin if all parts of the armor are not interconnected.

Over time even during regular usage cracks start appearing on the car body -it is made of steel only 0.8 mm thick, and it was not meant to hold the weight of 6.5 mm armor.

4. Our cars do not have ballistic gaps - the armor capsule protects 100% of the cabin. This increases the production time several times and requires a complete rework of the interior, but it is the only way to ensure reliable protection.

5. Our vehicles VPAM 7/9 have protection level on the glasses B7 (VPAM 9), and not B6 (VPAM 7), like regular armored vehicles. In most cases attackers shoot at glasses and glass is always the most vulnerable part. Hit of a 7.62 caliber bullet destroys area of about 3 sq. cm. on armor steel (a circle with a radius of 1 cm), and about 450 sq. cm. on glasses (a circle with a radius of 12 cm), i.e. 150 times more.

6. Our vehicles still look like the ones of the premium segment. We do not allow ourselves to simply glue carpet on the armor under the motto that it is an armored car - we do spend time and energy on creating completely new interior. More photos of our armored vehicles can be found here.

7. Our vehicles have a number of important features - for example, automatic deadbolts on the doors, a digital lock on the tail gate, defrosting and demisting of the windshield, emergency exit, etc. This provides convenience of usage and additional security measures.

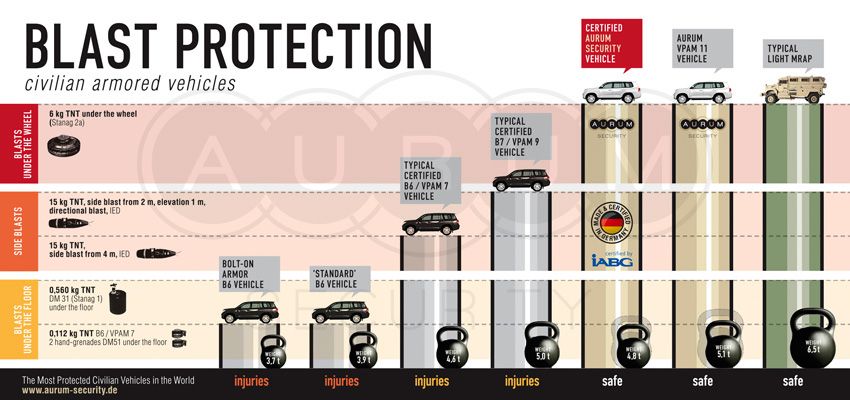

8. Optionally we can build protection of the vehicle against side blast of up to 15 kg TNT at a distance of 2 meters in accordance with the latest European and American standards, and protection against anti-personnel mines under the floor.

As a consequence of the above mentioned information the production time of our armored vehicles is 2-2.5 months, while many companies armor any vehicles to any protection level for 4-5 days only.

A B6 / VR 7 vehicle would be penetrated by any armor piercing bullet; our certified VR 10 vehicle will protect you from all soft core bullets and most of the armor piercing (AP) and armor piercing incendiary (API) bullets, including such a dangerous weapon as armor piercing bullets of Dragunov rifle.

This protection level is normally possible only for military vehicles, yet our vehicles retain comfort and inconspicuous look of civil SUVs. Please refer to the ballistic protection charts and blast protection charts for more details.

Attention! Beware of fakes - if you are not sure if the vehicle being offered to you by a third party has been produced by Aurum Security please send us the VIN code of the vehicle and we will double check that for you.Request detailed specifications

Protection VPAM 10

Ballistic protection:

- Opaque areas including the roof &provide protection according to VPAM APR 2006, level 10 / Stanag 3–. That includes all soft core bullets 5.56, 7.62, 9 and 12.7 mm and all wide-spread hard-core and armor-piercing bullets: 7.62×39 (BZ) Kalashnikov API, 7.62×51 (P80) AP, and 7.62×54 (B32) Dragunov API, from any angle (not only 45° or 90° as per BRV 1999)

- All transparent areas have thickness 80 mm and provide protection according to VPAM APR 2006, level 10 / Stanag 3–. That includes multiple shots of all soft core bullets 5.56, 7.62 and 9 mm and all wide-spread hard-core and armor-piercing bullets: 7.62×39 (Kalashnikov BZ), 7.62×51 (P80) AP, and 7.62×54 (B32) Dragunov API, from any angle (including 90°)

Blast resistance:

-

15 kg TNT at 2 m distance from the side of the vehicle, elevation 1 m

-

3 × DM51 grenades under the floor

-

3 × DM51 grenades on the roof

-

DM31 (anti-personnel mine) under the floor

-

Anti-tank mine (6 kg TNT) under the wheel (Stanag 2a) [optionally]

Protection VPAM 7/9

- 2×DM51 grenades detonated under the floor

- 2×DM51 grenades detonated on the roof

- Opaque areas VPAM 7 (B6+)Opaque areas including the roof provide protection according to VPAM APR 2006, level 7. That includes most of the soft core bullets 5.56, 7.62 and 9 mm, from any angle (not only 45° or 90° as per BRV 1999)

- Transparent areas VPAM 9 (B7, bullet-proof glass 65 mm)All transparent areas have thickness 65 mm and provide protection according to VPAM APR 2006, level 9. That includes multiple shots of all soft core bullets 5.56, 7.62 and 9 mm and the armor-piercing bullets of Kalashnikov 7.62×39 (BZ) and 7.62x51 (P80), from any angle (including 90°).

Highlights

- Hinges milled from a single piece of steel

- Single plate armoring of the doors

- Reinforced door frames

- Single piece hot-formed firewall

- The A/C system remains fully functional

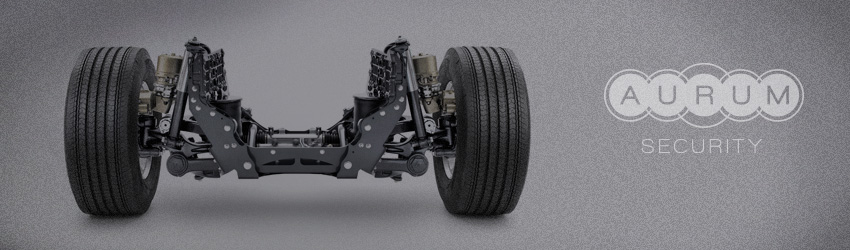

Suspension

To maintain driving dynamics and maneuverability of the vehicle we replace the OEM suspension with the one specifically designed to cope with the increased weight of the vehicle:

- 2 x Front Springs

- 2 x Front Mono-tube Damper Assemblies with Remote Reservoir

- 2 x Rear Spring

- 2 x Rear Mono-tube Damper Assemblies with Direct Mount, Stone Strike Protected, Reservoirs

- Front & Rear Anti-Roll Bar Assemblies

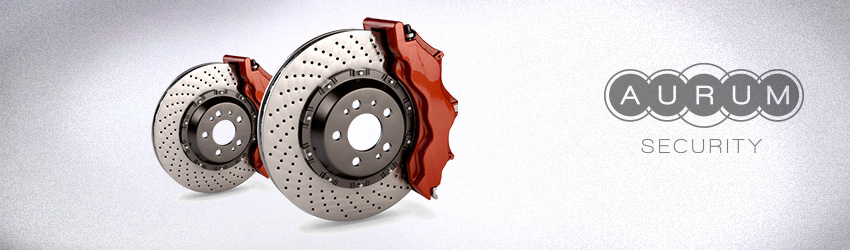

Brakes

- 2 x Front 6-Piston Forged Monobloc Caliper

- 2 x sets of High temperature Ceramic pads

- 4 x Heavy weight front and rear grooved discs

- 4 x Stainless steel hoses

- 2 x Rear 4-Piston Caliper